The Thermal Bypass Checklist Guide is put out by Energy Star to address the best practice ways to pass their Thermal Bypass Checklist. Passing this Checklist is required for a home to be qualified as ENERGY STAR. The following are excerpts from their guide and includes a link to download the Checklist Guide, as well as a link for only the Checklist itself.

The Guide contains General Tips and Best Practices on the best way to deal with the major problem areas in building homes:

- Overall Air Barrier and Thermal Alignment

- Walls Adjoining Exterior Walls or Unconditioned Spaces

- Floors Between Conditioned and Unconditioned Spaces

- Shafts

- Attic/Ceiling Interface

- Common Walls Between Dwelling Units

In response to significant changes in residential energy codes and standards, the United States Environmental Protection Agency (EPA) released a new set of guidelines for ENERGY STAR qualified homes, to be implemented in 2006. A major new requirement is the Thermal Bypass Checklist.

Energy Star Qualification

The Thermal Bypass Checklist is a comprehensive list of building details where thermal bypass, or the movement of heat around or through insulation, frequently occurs due to missing air barriers or gaps between the air barrier and insulation.

The Checklist must be completed by a certified home energy rater in order for a home to be qualified as ENERGY STAR, however, up to six items may be verified by the builder to minimize required field trips by the rater.

Air Barrier and Thermal Alignment

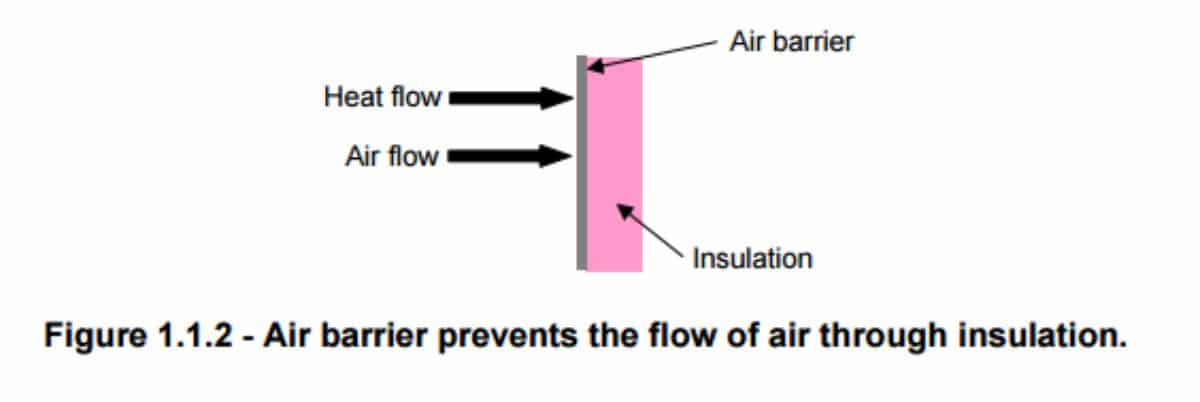

An air barrier is any material that restricts the flow of air through a construction assembly. In wall assemblies, the exterior air barrier is typically a combination of sheathing and either building paper, house wrap, or rigid board insulation, all secured with plastic cap washers. The interior air barrier is often an interior finish, like gypsum board.

A thermal barrier restricts or slows the flow of heat. This is typically accomplished through different insulation materials (e.g., fiberglass, rock wool, cellulose, polystyrene, polyurethane, vermiculite) and applications (batts, blown-in, spray foam, rigid board, and granules).

Regardless of which material and application is used, insulation is not fully effective unless it is installed properly – that is, fully aligned with a contiguous air barrier.

Insulation works because it incorporates air pockets that resist the flow of heat- that is, it slows the conduction of heat. This resistance to heat flow is measured by the R-value of the material. However, most insulation (with the exception of spray foam and rigid foam board) does not stop air flow.

Thus, for most insulation to be effective, a separate air barrier or skin is needed to stop the flow of air. For the air barrier itself to be effective, it must be contiguous and continuous across the entire building envelope, with all holes and cracks fully sealed, and it must be perfectly aligned with the insulation.

Minimize Thermal Bridging

Optimal Value Engineering (OVE) is one option to reduce thermal bridging through walls that uses standard building materials. In order to accomplish this, a framing plan is laid out as part of the architectural design that minimizes the studs and plates needed for structural support.

For example, 2x6 spacing can typically be increased from 16” on-center to 24” on-center. Further framing reductions are possible by lining up trusses with the studs so that only one, rather than two, top plates are needed.

In addition, “California Corners” that use two instead of three studs to frame corners saves on framing and allows insulation to span the full length of the wall.

Similarly three-stud framing assemblies at interior/exterior wall intersections can be eliminated by using furring lattice behind the exterior wall stud. This assembly reduces framing and allows for continuous insulation.

By adhering to these practices, it is possible to reduce the framing fraction from the standard 23% to around 15%. This 8% reduction in framing area would result in an 8% gain in insulation area. In addition to energy savings associated with reduced framing area, capital costs are reduced due to less framing.

Unlike advanced wall systems that can also be used to reduce thermal bridging (e.g., SIPs, Insulated Concrete Forms), OVE still needs to address quality control issues with insulation installation to ensure continuous alignment with the air barrier along with no gaps, voids, and compression.

Using the Thermal Bypass Checklist Guide will result in an energy efficient log home that can qualify as Energy Star rated. Along with the thermal mass inherent in a log home, it will provide you with a green cabin that is optimized for comfort and high performance for many years.

Shop Related Products

More Cabin Efficiency Pages:

Solar Power Saves Money and Resources Both passive solar power and active solar power offer ways to save money along with our planets resources.

Log Home Systems – An Integrated Approach Using an integrated approach to log home systems will result in greater efficiency, lower building costs, superior performance and overall savings.

Optimal Value Engineering Optimal Value Engineering is a mindful design process that minimizes waste and increases efficiency.

Thermal Mass Effect of Logs The thermal mass effect of solid logs makes cabins energy efficient.

Energy Efficiency of Log Homes The high energy efficiency of log homes is due to the thermal mass effect.

Leave a Reply